Sometimes we can hear the question of which is the best diesel generator set manufacturer and think about it. This article may be helpful to answer some doubts.

How to find the best manufacturer of diesel generator sets?

First, if you haven’t seen it yet, we wrote a very complete article on how to buy a generator. Moreover, how to know how much power you need? Now going back to the article, we realized that this question is quite generic and ends up generating different interpretations. Hence, we separated this article into topics to help to understand.

Gasoline Generator x best diesel generator set manufacturer

One of the first doubts is the differences between the two types of generators. There are pros and cons. Now let’s get to them:

Gasoline Power Generator

Eventually, Gasoline generators can be 2 and 4 strokes. They have some hallmarks of all gasoline engines.

Pros: They are quieter than diesel engines. This has greater meaning when there is public service. That is, it makes no sense to leave a diesel generator close to your customers. Likewise, the 4-stroke engine is much quieter than the 2-stroke engine. (We’ll talk more about electronic generators below, which are the quietest on the market).

Cons: They have higher fuel consumption, that is if you need the best diesel generator set manufacturer to run always, instead of just as a contingency.When the power goes out. Finally, a diesel generator is vital.

That’s because gasoline generators may even be cheaper, but they spend more over time. In addition, they are more complex engines, making them more likely to break down.

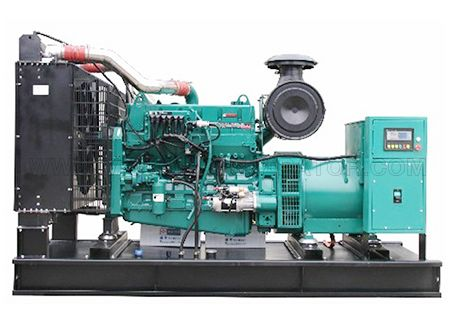

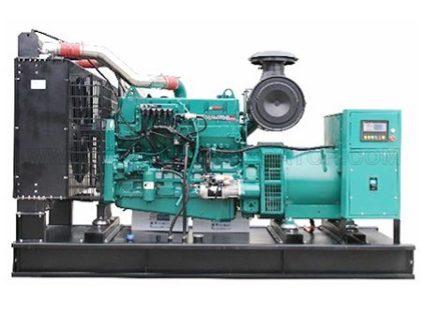

Diesel Power Generator

Pros: They are more robust generators. That is, they have greater durability compared to those powered by gasoline. Likewise, diesel is a cheaper fuel, so consumption over time ends up paying for your higher initial investment.

Cons: In addition to making more noise, which can be a nuisance depending on the situation, diesel engines pollute more, which is not ideal when your concern is to preserve the environment.

Digital Gasoline Power Generator

Pros: They are generators with great efficiency and economy. They automatically adjust the best diesel generator set manufacturer engine speed to the load used and are much quieter. It is ideal for those who deal with customers and need the generator close by.

Cons: Due to the technology employed, its cost is much higher compared to generators of the same power. Tools and even essential devices for the lives of patients are necessary. In hospitals, we cannot even think about not having a powerful generator supporting their own energy production.

If this is your case and you need an uninterrupted source of electrical energy 24 hours a day, you must think that the best diesel generator is your best choice, right?

With this article, we intend to eliminate your doubts to help you close the best deal.

Best Diesel Power Generator

Currently, the best diesel generator set manufacturers of all the brands in the market that operate in the segment of power generator groups offer diesel models of the most varied powers.

The topic about which is the best brand on the market is a very controversial question, as there are more than one brands that stand out in the category of generators, especially if we evaluate its reputation among consumers.

Diesel power generators

First of all, it is necessary to clarify that it is possible to find gasoline and diesel power generators on the market. In this post, we will only cover the models of this second category.

A diesel-fueled power generator is the most suitable for the professional segment, whether in hospitals, industry, civil construction, agriculture, supermarkets, or in the field of sports and entertainment, whether in large matches, shows, or concerts.

Diesel equipment

It is indicated for all cases where there is a need for continuous use of energy. This is because, as diesel is a cheaper fuel than gasoline, it will make it possible to reduce costs for the operation of the generator.

What are the expenses of diesel equipment?

The expense with the maintenance of diesel equipment is also considerably lower when compared to the gasoline model since in this type of generator, there is no carburetor or spark plugs. The best diesel generator set manufacturer is more robust and resistant, providing more durability and efficiency in its operation.

How can we achieve the level of excellence?

A diesel generator is usually made with high-quality materials. Moreover, this increases its cost in the market. Therefore, these models are usually more expensive than gasoline appliances. However, even being higher, the initial investment is easy to recover during the generator’s use time, through savings with the refueling value of the fuel in question.

Characteristic of a diesel generator

The crucial production of intense noise, precisely because it is equipment with greater power. In addition, these best diesel generator set manufacturer models are also often more polluting than gasoline generators.

Diesel power generator at the best price

If your business depends on the uninterrupted supply of electrical energy, you should purchase a diesel power generator so as not to compromise the productivity of your business. There are many companies that work with energy solutions for small, medium, and large companies, and, for sure, they should have the ideal model to meet your demand.

Commonly, known for their high power, diesel generator models are way in demand.

Because of this, its use is important for places where there is a greater need for the generator. But there are also options on the market with lower power (starting at 7KVA), for places that are leaner or that do not need constant energy.

Benefits of best diesel generator set manufacturer

It can stay on for long hours, which means it can be good to use as a fixed source of power. And your fuel is cheaper, offering a much greater cost-benefit.

For this reason, diesel generators are best for:

- Supermarkets and shopping malls;

- Miscellaneous events;

- Hospitals;

- Large industries;

- Condominiums;

All these places need constant power distribution and the diesel generator comes in as an economical source. In addition to being a necessary resource in cases of failure, its high power also draws the attention of condominiums and residential buildings, which constantly suffer from a lack of energy.