Plastic injection is simple, reliable, and very efficient, so injection mold-making companies use injection molds in the routine of industries and companies. However, this process requires experienced professionals in the market and a quality injection molding machine. Otherwise, the final result will not expect.

Discover the main benefits of using injection molds:

For the injection molds to take on their detailed shapes, high pressure will be on the plastics inside the molds. This force will make every detail of the piece come out perfect, exactly as it should be.

In addition to this precision in the details, with the pressure on the molds, it is still possible to give complex shapes. Some other processes would be much more expensive and would not have the guarantee of efficiency as in injection molds.

Agility without losing quality

Custom injection mold company designs and takes them to the presses duly pre-programmed, according to customer’s requests. From the beginning, the steps are fast, drawing attention to plastic production by injection. This agility makes the process more efficient and faster, thus increasing the production rate.

The molding process is reinforced by filling the molds

The molding process is efficient for a number of reasons, one of which is its strength, which can reinforce by filling the molds. With this technique, it is possible to reduce the density of the plastic at the same time it molds, so that it does not lose its shape.

For an injection mold-making company, the manufactured parts need to be strong and have greater durability. Therefore, plastic injection has this option since other molding processes do not provide the same resistance.

Several types of plastics in a single mold

The versatility of this process allows molds to produce not only with one type of plastic but with several simultaneously. To obtain this result, the practice carries out by co-injection molding.

Process automation

The entire plastic injection molding process is automated. Robots and machines can do the job, but an operator needs to control and manage these machines so that they maintain production efficiently.

As in any other area, this automation helps reduce costs without losing quality in the final product. This makes it easier to pass on reduced value to the injection mold-making company.

Finished parts right out of the machine

Once the parts are produced by injection molding, they will not need finishing or any other type of post-production. After being ejected by the machine, the part finishes in the desired design and is ready for use.

The environment

Although plastic is a topic in conflict with the environment, this process earns some points when we refer to sustainability. This is because the material used in the production process is reused, giving a new function to a product that would otherwise be discarded. As a result, injection mold-making company generates little waste.

The molding processes

It all starts with the manufacture of this mold, where a designer will carry out an analysis of the project’s needs and will create from there a mold of exact shape, with all the necessary specifications to have the greatest possible precision of details.

All stages of this process involve heating the raw material, injecting the mold, and cooling it. One by one the parts mold following the cycle of closing the mold, injecting the molten material, cooling, opening the mold, and removing the part.

Specialists in the project and product development

TIP-TOP Molds has experience in the plastic parts production market through injection molds. We are specialists in project and product development. In addition, we have software, and a team prepared to meet your demand with a high level of quality and finish.

Injection mold making company and prototyping

We have a high technological capacity to produce functional prototypes. This will give your project even more exclusivity and efficiency.

Injection mold manufacturing

We are strictly complying with deadlines and maintaining precision in the details. We have modern tools to develop plastic molds for the most varied segments.

All the novelties in the plastics market can find at TIP-TOP. As a result, our entire production relies on highly technological machinery.

The capacity of injection molding machines

With the capacity to process up to 2,000 tons of thermoplastics per month, the injection mold-making company has 30 injection molding machines from 60T to 2100T, injecting up to 20KG per injection. We meet and adapt our quality standards for large and small companies to suit your product type.

It is widely known that plastic injection molding can consistently produce thousands or even millions of plastic components. Products for consumer goods manufacturers, aftermarket parts suppliers, packaging companies, and automotive lines.

Injection mold making company complexity and composition

Plastic injection molds have the ability to produce a wide variety of products that vary in size, complexity, and composition. Applications for this highly repeatable and reliable process range from the simplest to the most complex parts.

How it works:

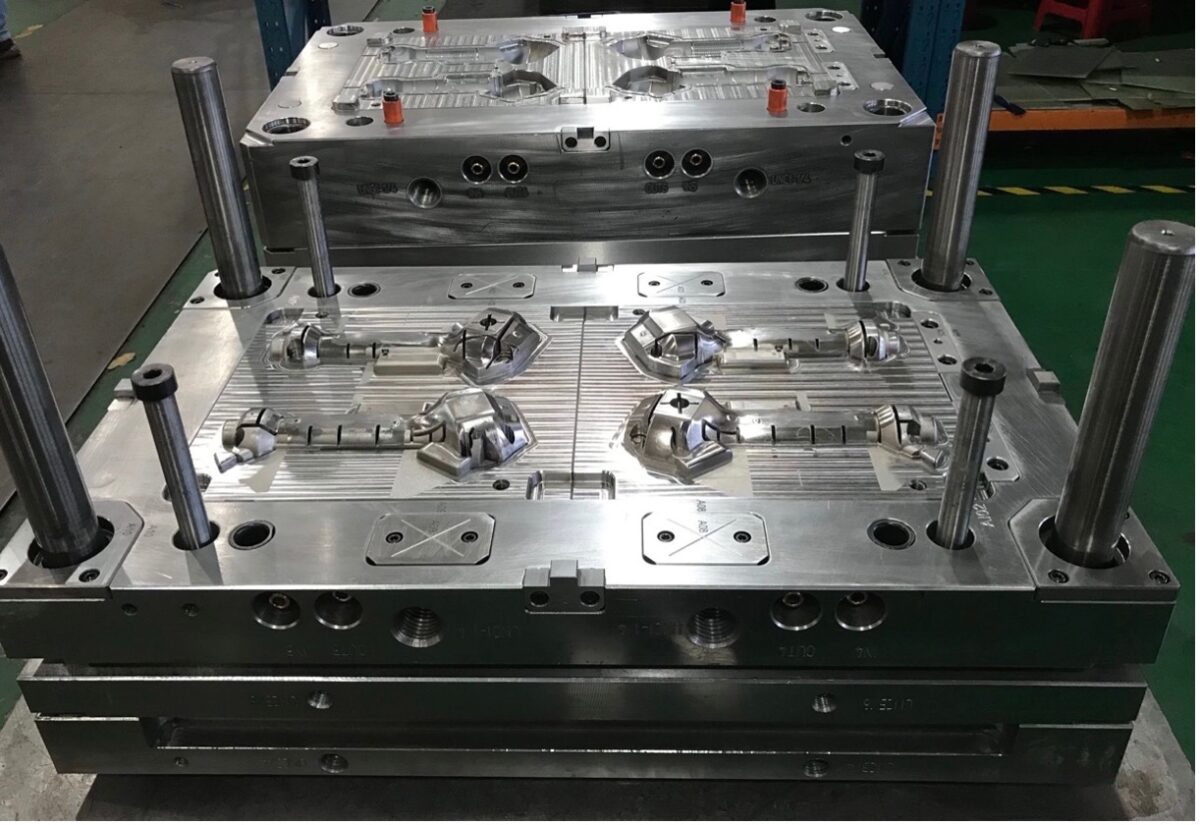

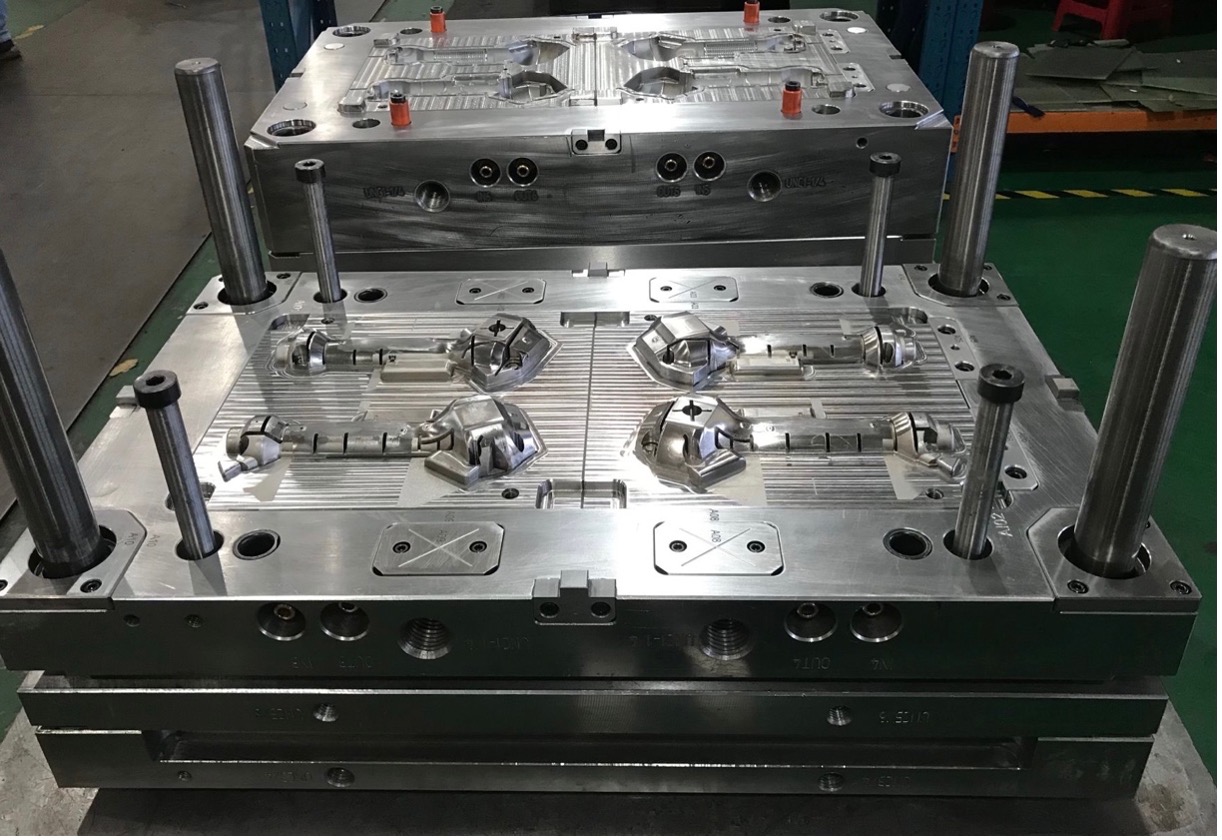

Once a part has been designed by a product engineer. The tool shop will create a mold, usually made of steel or aluminum. The mold can be a single cavity or multiple cavities, precisely machined to form the desired part.

Various polymers, including thermoplastics, thermosets, and elastomers, can be used in injection molds. Pellets of the chosen material heat in the gun of an injection molding machine. The mixture is flexible enough to inject into the mold.

In the injection mold-making company, a screw-type plunger forces the correct volume of material to fill the cavities under pressure. The two halves of the mold clamp tightly together. The material cools and solidifies in the cavity and is then removed from the mold by ejector pins.

Injection molding follows a four-stroke cycle.

First, the mold cavity fills with molten material, then the material quickly cools, causing it to harden (become solid). Then the mold cavity opens, exposing the part and giving it a space to exit, which happens when it finally pins out.

What is injection molding for?

There are several significant advantages to using an injection mold-making company. Here is a list of the most relevant:

Injection molding can be fully automated, allowing for very high production rates.

In conclusion, you can use a variety of materials in injection molds. Combine different materials to synthesize desirable material properties in your plastic product. The combination of more than one injection-molded material (usually two different materials) is known as co-injection molding.

There is typically very little waste during injection molding as excess material can easily repurpose.