The New Auto-unscrewing mould for Plastic Parts

Your Comprehensive Guide on Auto-unscrewing mould for Plastic Parts

Do you want to speed up the cycle time of plastic molded parts dramatically? If yes, then you should opt for an auto-unscrewing mould as it is the best way to fasten the production process. Apart from drastically speeding up the production process, it offers many other advantages to both the engineers and the manufacturers as well. Want to know more about this type of molding? Keep reading then. You will find everything you want to know below.

Introduction

The plastic molded parts come with injection threads that you need to unscrew. While you can unscrew the parts manually on short-run and prototype molds, this is not the case in high-production molds. This is where auto-unscrewing mould comes to your assistance. It not only helps you unscrew the parts efficiently but also speeds up the production process.

However, you need to keep in mind that the cost of this type of molding can be extremely high as compared to the short-run molds. That’s why this method is specifically suitable for high-production molding.

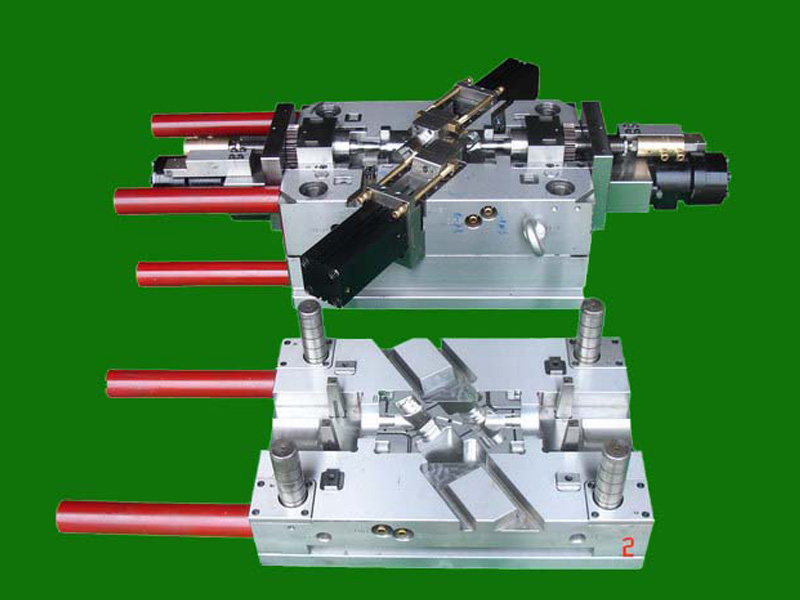

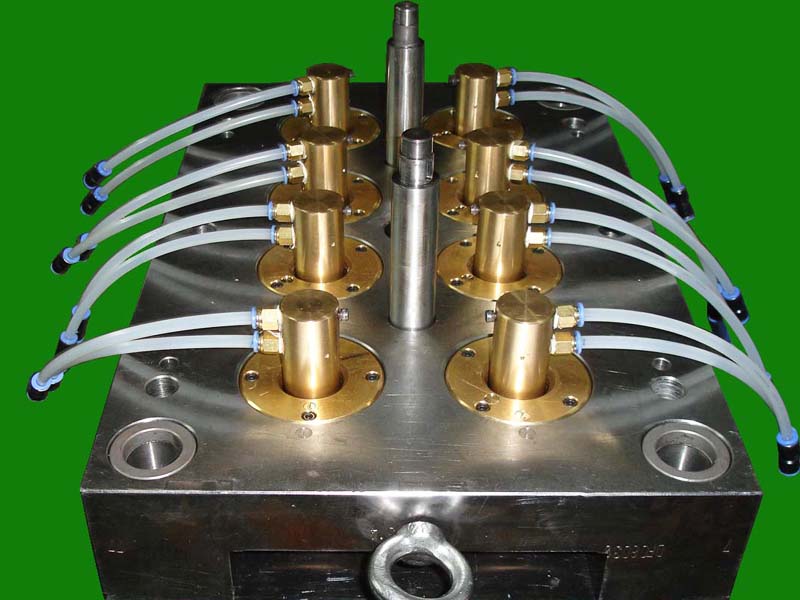

The engineers accomplish the process with the help of electric or hydraulic motors. In addition to this, the precision-made cores have also threaded ground on them. Moreover, they attach the bearings as well to keep them in the correct position.

The manufacturers also attach gears to the cores that help them engage with the main drive gear. There is a chain attached at one end of the main drive and it is attached to the motor at the other end.

The motor starts turning to the main drive gear when you open the mold. This helps in turning the threaded cores. The engineers hold the part in place with the help of the serrations or ribs. As a result, the parts automatically unscrew and then fall off the core.

In some injection molding processes, the engineers even use a pinion and a rack to unscrew the part automatically. Not only this, but they sometimes also use collapsible cores. These collapsible cores have segments in them that collapse. As a result, the parts fall off the thread.

The Process of Auto-unscrewing mould for Plastic Parts

The entire process of the auto-unscrewing mould for plastic parts is based on the four main steps. Let’s take a look at these steps below.

- In the first step, the engineers inject the plastic into the mould. Once the plastic has cooled down, the automatic cores start unscrewing themselves. The entire mechanism is based on a pinion and a rack and is powered with the help of a hydraulic cylinder.

- In the second step, the rack turns into three sets of gears. These sets then retract the threaded cores into the ejector box.

- After the cores are fully unscrewed, you will notice the opening of the mold. When the mold opens, the ejector system forces a stripper plate forward. This helps in the ejection of the parts.

- Once the part is fully ejected, it helps in reversing the hydraulic cylinder and screwing the threaded cores back into the original molding position. The entire process then starts repeating.

Major Advantages of Auto-unscrewing mould for Plastic Parts

The auto-unscrewing mould for plastic parts offers many advantages to the users over manual unscrewing. Let’s take a look at a few of them below.

1. Detailed Features

The plastic molds are exposed to very high pressing factors. Accordingly, the plastic inside the molds is squeezed more earnestly against the form contrasted with some other trim cycle. Because of this exorbitantly high pressing factor, it is feasible to add countless subtleties to the plan of the part. Besides, because of the high pressing factor during the trim interaction, you can plan and make mind-boggling and multifaceted shapes. Otherwise, it was not possible before.

2. High Efficiency

Another advantage of auto-unscrewing mould for plastic parts is the high efficiency that you get from the process. All the clients need to do is design their specifications and pre-program their presses. After this, the actual process is very quick and efficient. It hardly takes any time and allows the manufacturing of more parts from a single mold. As a result, the process becomes more cost-effective as well.

3. Enhanced Strength

In the process of auto-unscrewing mould for plastic parts, it is feasible to utilize fillers in the infusion molds. This filler decreases the thickness of the plastic during its shaping and helps in adding more prominent solidarity to the part after it has been formed. In fields where parts should be solid, the plastic infusion has an alternative that other trim cycles don’t offer.

4. Saves Manufacturing Cost

Plastic infusion forming is a computerized interaction. The advanced mechanics and machines perform a larger part of the infusion shaping cycle which a sole administrator can handle and oversee. Robotization assists with diminishing assembling costs. This fundamentally decreases the overhead cost. Moreover, with a diminished workforce, the general expense of assembling the parts is decreased and this expense saving can undoubtedly be given to the client. Moreover, computerization considers making precise infusion molds. PC supported plan (computer-aided design) and PC helped to produce (CAM) permit close resilience during the creation of the molds.

5. Ability to Use Multiple Plastics

Last but not the least; the auto-unscrewing mould technology helps the engineers to use multiple plastic parts simultaneously. You can do this with the help of co-injection molding. Thus, you no longer need to worry about using a specific type of plastic at one time. You can use as many plastics as you like.

Final Words

So, if you also want to speed up the production process, you should also adopt the auto-unscrewing mould technology for your plastic parts. However, you should keep in mind that this process is only available for plastic parts of large volume. Need more information? Welcome to contact us now!