Research

-

-

-

01

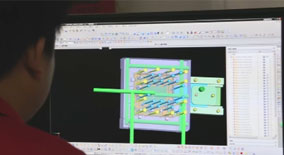

Further Design Discussion

According to the mold request and DFM, we would discuss the further design proposal, delivery date, machining technology, optimum slide stroke, lifter stroke, hydraulic cylinder stroke, and the perfect cooling lines.

-

-

-

-

02

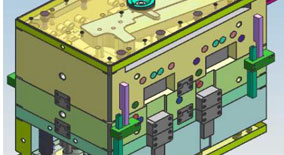

To Optimize the 3D Mold Design

To find a proposal for optimization of the PL lines, venting slots, cooling circuits, gating way, and the ejection stroke.

-

-

-

-

03

From 2D to 3D Design

If needed, we would supply detailed 2D and/or 3D mold designs to our customers, including ejection system, gating system, venting slots, inserts, slides, lifters, hydraulic/air cylinders, and the auto unscrewing mechanism.

-

-

-

-

04

Mold Design Approval

According to the customer’s request, we would send our 2D and/or 3D mold design to our customer for approval. We would improve the mold design per the feedback from the customer till the mold design is approved.

-

-

-

-

05

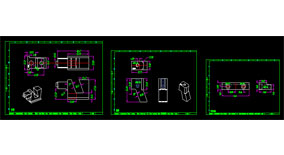

To Output All the Machining Drawings

Based on the 2D and/or 3D mold design approved, our team would output all the machining drawings, BOM form and make the Technique card for each component.

-