Custom Injection Mold Manufacturing in China: The Best Company in 2022

Today, it is almost impossible to imagine life without plastic products. These are common in the manufacture of many household items, and due to their physical properties, they allow you to create products of the most incredible shapes and sizes.

An efficient and widely common method for all kinds of plastic items

Plastic items are common almost everywhere – in medicine, manufacturing, electrical engineering, construction, shipbuilding, and automotive.

How does the plastic injection molding process work?

The whole process of injection molding can be conditionally divided into two stages: preparatory stage and main stage.

- During the preparatory phase, a 3D model of the product comes according to the customer’s descriptions, photographs, or drawings. Next, a prototype of the future finished item is possible to develop. Based on the CAD model, after checking the prototype, a plastic injection mold is designed.

At the preparatory stage, testing of the prototype and the first copy of the product is carried out, this is necessary in order to identify possible inaccuracies and flaws in the designed 3D model or injection mold.

Products depend on high-quality and accurate preparation

The quality and service life of products depend on high-quality and accurate preparation. Our experts will competently advise on the choice of the necessary raw materials for the creation of a particular product.

- The main stage of the injection molding process includes the following points: plastic injection, molding & mold cooling, product ejection.

We will make the molds you order fully meet all requirements

Our specialists will try their best to meet all your requirements, based on their experience, and knowledge.

Calculation of the cost of injection molding services

When calculating the cost of injection molding in China, the following factors are taken into account:

The complexity and parameters of the product

Order volume: the higher the volume, the lower the cost of one product.

Advantages of the method

- Using the injection molding method, you can get a part of any size and complexity. The design of the manufactured mold takes into account the smallest details, many bends, and holes of the planned product.

- All aspects of the molding parts to produce are taken into account during the preparatory phase at the time of testing.

- Designed before production, the high-pressure injection mold has great strength. However, do not lose sight of the fact that it has a certain resource, which is selected based on the requirements of the client. This resource is limited by the amount of closing/opening of the form.

- The presented method is successfully common in large-scale production.

The practical significance of injection molding

Thanks to the high-pressure injection molding method, almost any plastic product can be made:

- Kids toys

- Plastic packaging, caps, caps, etc.

- Enclosures for electronic equipment

- Enclosures for medical equipment

- Component parts for the automotive industry, etc.

Injection Molding technology for the production of plastic products

To date, the most popular method for the production of plastic products is injection molding. It assumes the possibility of automating the process, gives excellent results in a short period of time, and does not require any additional work with the produced parts.

Usually, the resulting parts can be recycled, so plastic injection is also environmentally friendly.

Injection Molding technology includes several operations

First of all, it is necessary to dry the thermoplastic polymer granules, which are the main material for obtaining a new product. The granules should not contain more water than the production requires, so their drying is required.

Thermoplastic polymer granules

Before injection molding, the pre-processed material enters the receiving hopper of the TPA (injection molding machine) with the help of an operator. Further, the machine itself works with the raw material. It guides the pellets into the melting screw, and then, with a special piston and high pressure, the raw material will be quickly poured into a mold. Now the mold has only to cool down so that you can get a molded part.

How does an injection molding machine work?

The main parts of the custom injection molds are the plasticizing unit and the clamping unit. Moreover, the work in them is provided by hydraulic actuators, an electric motor is responsible for the pressure. Numerical control (CNC) is common to form a specific product.

This mechanism monitors the fulfillment of the established characteristics during the process and regulates various external devices (for example, the same hydraulic drives, electric drives, heating elements, etc.).

The maximum possible injection volume

Of course, in each specific case, it also depends on the capabilities of the molds. However, there is a limiting possibility of the apparatus itself – one can simultaneously serve a larger number of injection volumes, and the other a smaller one. The unit of measurement is grams or ounces. Although we are talking about volume, in fact, it is a mass of material.

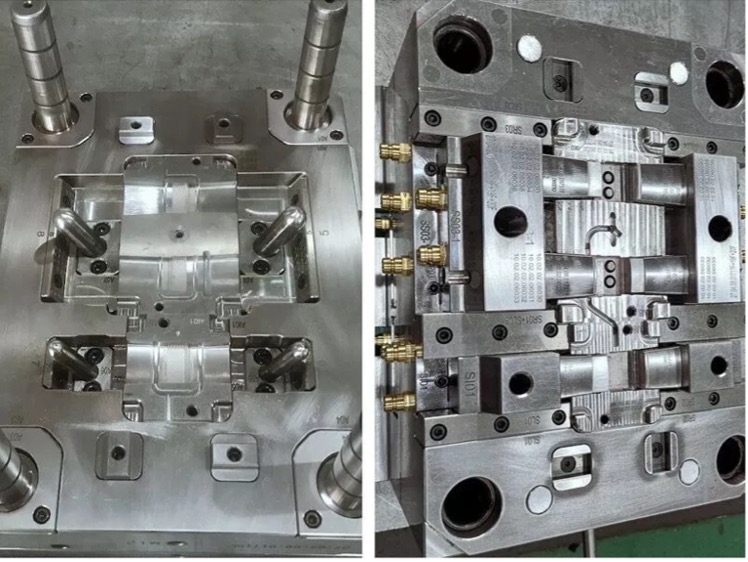

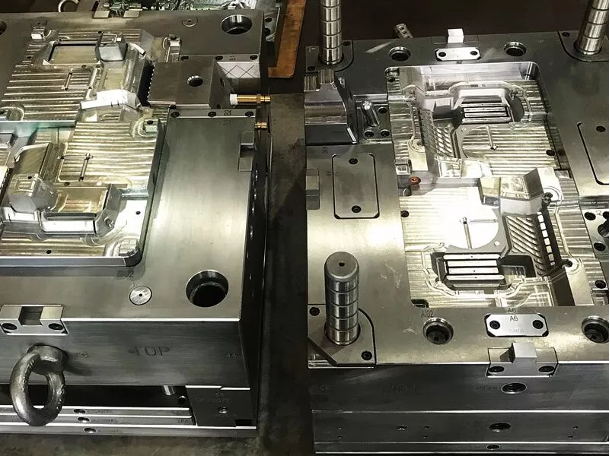

The characteristic of custom injection molds

The characteristic refers to the injection unit and means the constant value required to influence the melt during the entire working cycle. Moreover, distance from one guide plate of the machine to another. That is the maximum width of the molds common.

The lack of one characteristic of the machine is easy to make up for by an excellent indicator of another. For example, to increase the pressure, it is enough to reduce the screw radius. However, in this case, the maximum allowable injection volume will also decrease.

At the same time, an increase in pressure will cause a corresponding increase in the opening force of the custom injection molds. It is not scary if the injection molding machine is able to enhance the closure. Otherwise, you need to replace the injection machine with a smaller one.

Injection molding methods

Different methods are common for different injection molding tasks. The most common of these is injection. It provides a rapid injection of material into the mold under high pressure. The intrusion method is common for molded parts with thick walls, the material enters the mold in the form of a spinning “worm”.

Injection molding is advantageous to use in the manufacture of large parts. Moreover, multi-layer custom injection mold in China involves the production of multi-colored parts from several materials, etc.

What plastics can be common?

Injection molding produces plastic products that are able to melt again. These are:

- Polyethylene

- Vinyl plastic

- Acryloplast

- Polyamide, etc.