Custom Injection Mold Price in China: 2022 Top Company

To form a correct idea about the calculation of the custom injection mold price in China, we have made a convenient infographic with numbers for you:

Prices of custom injection mold

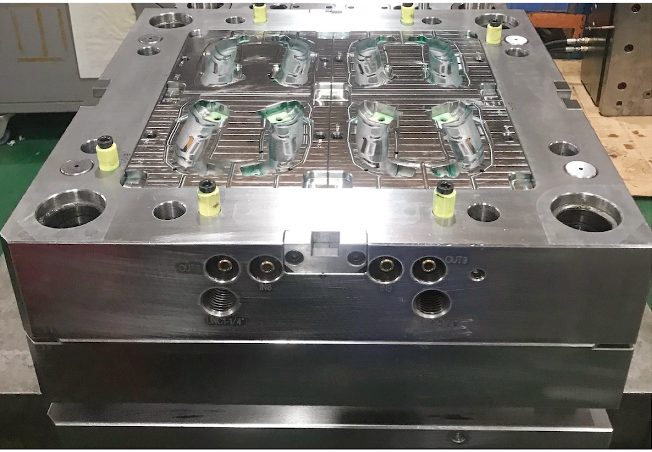

The costs of tooling are different. The mold life depends on the size, configuration, and steel quality of the molds. Sometimes, the injection mold is sufficient for the production of more than 1 million shots. One injection shot can produce up to dozens of products. We built a mold with 32 cavities a few years ago.

This means that the mold can produce millions of items. After the mold has been worn out, it can be restored. The cost of restoration is usually no more than 25% of the original cost. Mold production time is about one month to two months.

Material Selection for custom injection mold in China

Services for the manufacture of plastic products are understood directly as services for the molding of plastics. Moreover, this means that the price does not include the cost of material and tooling. It should also include ALL necessary additional services, such as commissioning, configuration, test run, processing, and packaging of the final product.

The price includes ALL necessary additional services, such as commissioning, configuration, test run, processing, and packaging of the final product.

How do we calculate the cost of molds and molded parts?

Each company dictates its own prices for the manufacture of plastic products and parts to order. The custom injection mold price in China usually includes the material from which the product is made. The operating time of the equipment and plastic molding is important. Moreover, the inspection of parts, as well as packaging and shipping is vital too.

It seems that with such a list, the price should be high. But modern technologies and technical equipment can save the time of manufacturing the product. Moreover, it reduces the price of the production of plastic parts.

A high-quality and proven product with little money

Our company tries to make sure that the client receives a high-quality and proven product with little money. Each product calculates individually, but there are some general rules for it.

We can offer you a wide range of different plastic parts, including different shapes and complexities. Moreover, our prices for the manufacture of plastic parts will pleasantly surprise you. In addition, we always provide discounts to regular customers.

The use of plastic in the industry

Plastics are raw materials that are widely common in various industries. The main property of this material is its ability to take any desired shape. All this explains the popularity of raw materials in the production of a huge number of products.

Why is plastic so in demand by modern manufacturers?

The relatively low price in China of raw materials reduces the cost of the final product. Moreover, in a market economy, its wide application is a weighty argument. The main industries that use plastic:

When creating expensive complex devices, the ability to use high-quality, but inexpensive materials is a real find.

It was the replacement of most unloaded metal parts with plastic ones that made most of the once expensive machines and devices available to the average user. Moreover, almost all equipment, tools, auxiliary parts, all kinds of components could be made from plastic material.

Plastic is common in the medical industry to make components

Plastic is common to make components for medical instruments and devices, containers for storing medicines, and ampoules. In surgery, plastic heart valves, prosthetic limbs, and teeth are common. The handles of crutches and devices for people with diseases of the musculoskeletal system are also made using this material.

They are also common as packaging for seed

Agriculture. Here, polymer films have found the widest application as a covering material for greenhouses, fruit, and grain storage facilities. Moreover, they are also common as packaging for seed, in the creation of irrigation and cultivation facilities, garden tools.

The necessary outlines and dimensions are given to plastic by molds. They are a container where the molten raw material pours, where it cools down, acquiring the necessary hardness.

Custom injection mold price in China: create a large series of plastic products

Plastic injection molding allows you to create large series of plastic products for various purposes, which are completely ready for further use. The method of plastic injection molding carries out on special injection molding machines – injection molding machines (TPA).

With the help of injection molding machines, more than a third of all-polymer products create in the world. Moreover, we offer services for the creation of a large series of plastic products to solve your problems.

Plastic injection molding: large series

The popularity of the technology explains not only by the custom injection mold price in China of the finished product but also by a wide range of materials:

- Polypropylene(PP)

- Polycarbonate(PC)

- Polystyrene(PS)

- Polyethylene(PE)

- Polyamides(PA)

Moreover, products made on injection molding machines (TPA) have qualities that are difficult to estimate:

- The product can be absolutely any color, even translucent.

- The surface is scratch-resistant and smooth to the touch

- Frost resistance (up to -57 degrees Celsius), high impact resistance, and rigidity.

- High elasticity, resistance to deformation, and whitening under load.

- Resistant to chemicals and UV radiation.

- Possibility of application in food and medical branches.

- Good organoleptic properties and tightness.

Manufacturing for a custom injection mold in China

Injection molding for plastic products of a large series is impossible without a mold. Creating a mold is a very crucial process.

Our specialists are ready to take on the development and manufacture of molds for plastic injection molding according to your technical specifications. Moreover, the price of developing and manufacturing molds calculates depending on the complexity of the final product.

We can offer you the production of the various types of molds for injection molding of plastic products:

Calculation of the cost of the mold

Designing a custom injection mold in China cannot begin until you have a technologically correct 3D model of the product. But, as practice shows, the calculation of the cost of manufacturing this form will correctly perform, in every sense, if there is a 3D model of the product (s) you need.

Conclusion

Our specialists, who are well specialized in plastic injection molding, will check and, moreover, if necessary, will also discuss with you any possible changes in order to maintain the manufacturability of the product in relation to its production by injection molding.

At the same time, our mold price and molding price are competitive, which will make you satisfied. Welcome to send us an RFQ and place a trial order.