A Sneak Peek into Overmolding Prototype Technology

What to Know About Overmolding?

Overmolding is a manufacturing process where resin and surfactant are added in an article of manufacture. This creates the feeling that it is dipping in chocolate or putty for example, which leads many people to refer to these objects as “resin castable.” Overmolding is described as a process where one part of the product, usually an insert or shell-type item such as a case for your phone and screen coverings is creating to using two different materials. The first material (substrate) becomes partially covered with additional layers during production; these subsequent molding surfaces are called “overlays.”

What Exactly Is the Substrate?

The substrate is the primary piece in what will ultimately turn into a solitary nonstop part made out of synthetically reinforced and frequently precisely interlocked materials.

It could be anything, from metal machined parts to plastic molded products or even threaded inserts for screws; all made by brazing together various pieces that are designed specifically for this purpose!

What is the Overmolding Material?

The Overmolding Material is a plastic that is mixed with additives like colorants, foaming agents, and other fillers. It begins as pellets in pellet structure before they are warm-up to their dissolving point. So it tends to infuse into the form tooling when you press “submit.” now and again.

However, there are limits on what materials function admirably for this interaction on the grounds that not all plastics will bond together pleasantly – particularly on the off chance that one piece of your end result requires metal parts all things being equal!

What Is the Purpose of Overmolding?

The overmolding process is useful for a number of reasons, but the most common material is toothbrushes. They are often applied in order to create tool handgrips and handle cordless drills or screwdrivers with ease!

In addition, it’s also possible that you’ll come across personal care products like shampoo bottles and razors if your project involves those kinds of items as well.

Here we discussed a few examples of typical overmolding applications:

Plastic Over Plastic

For those who want their product to stand out, over-molding is a great way of doing it. Plastic Over Plastic – first you have the rigid plastic that’s being molds into an object or design on top another layer which is texturing and/or colouring differently than its sibling.

Rubber Over Plastic

To give something a soft grip, you can use rubber over plastic. A rigid plastic is first molded and then the TPE (or other type of accessory) will be applied to or around it in order for its surfaces to come into touch with each other so that user feels less resistance when gripping onto them firmly.

Plastic Over Metal

Many industries rely on overmolding to create a part with the desired characteristics. Plastic Over Metal is one example of this process, where first metal parts are machine and then inserting into an injection molding tool so plastic is adding around it for shape or coloration purposes- often capturing these components in between two pieces that are original designs without them being there at all!

Rubber Over Metal

Overmolding can be used in a variety of ways, often to give some extra grip or cushion. One common application is rubber over metal. First, the surface needs machining before casting it with either natural rubber-like silicone-based ones. Which are more durable than their synthetic counterparts. However, they are still soft enough not to cause discomfort when pressing against them for long periods. Then you put these into injection molding tools so that your final product gets forming around its base material (in this case both hard and plastic).

You could use TPE instead. Thermoplastic polyurethane elastomers provide better traction on smooth surfaces without being too bulky at all times.

A Few Things to Note:

A product can have more than two materials. Some products use three different surfaces on one part in order to achieve color breaks and grip, like scissors!

How is the Overmolding Process Typically Performed?

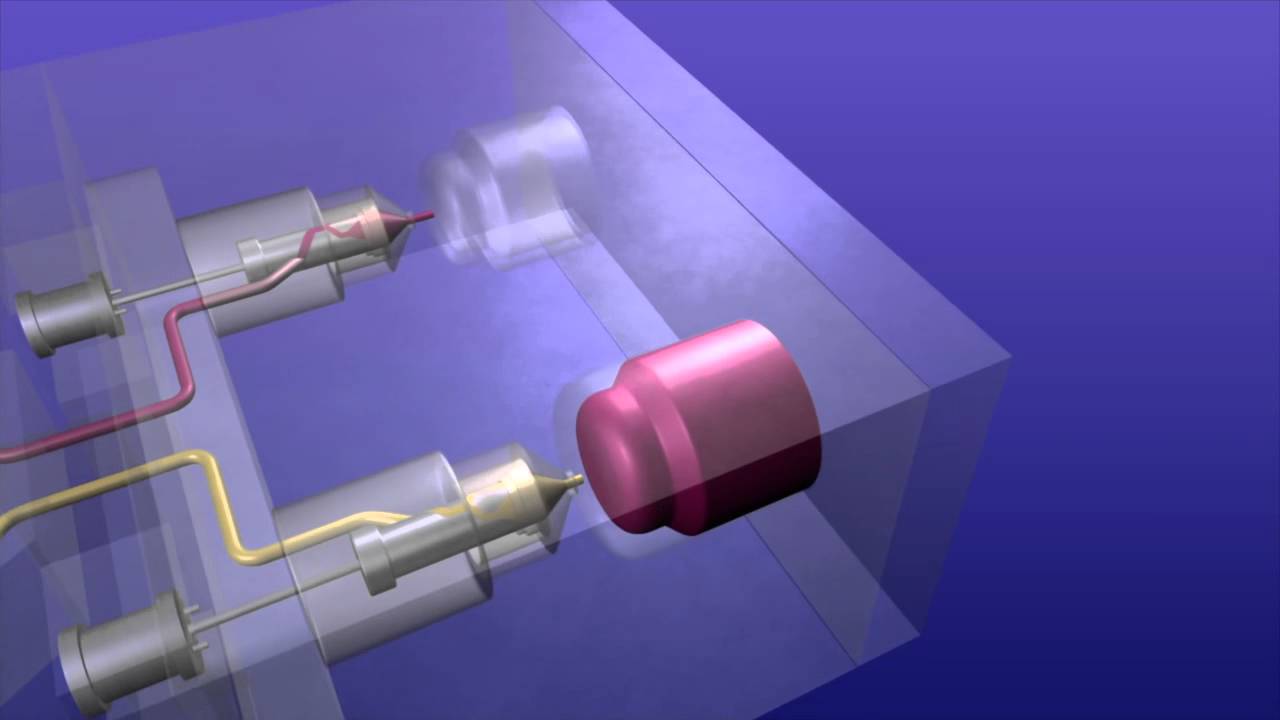

Injection Molding is a process that overcomes many of today’s manufacturing hurdles. Overmolding has been around for years, but it continues to grow in popularity. There are so many benefits when compared with other methods like casting or pushing parts through a die using machine tools. This includes improved precision and surface quality, as well as reduced energy consumption due to less tool, wear common during machining operations.

Injection molding goes one step further by allowing manufacturers greater control. They can change certain physical attributes such as Power grip Strength (the strength required before breaking), parting lines pattern density location, etc.

A good idea is to make sure your substrate and overmolding materials interlock. Bonding these two together will not only be done chemically but also physically. With the use of mechanical components that connect both pieces in some way or another.

Overmolding Standards for Prototypes

Overmolding can be a quick and easy way to add details to an already existing model. For example, at tiptop molds, we use our overmolding service for creating prototypes with soft rubbery materials that will quickly cure in just 30-60 seconds!

We are also able to control the color or hardness depending on what part needs extra attention. While using injection polyurethane casting resins results in parts being less costly than other manufacturing methods. Such as plastic molding steps often associated with mass production plastics goods.

Why Would you Want to Overmolding?

There are a lot of reasons to over mold. Among the most common, you can do it for aesthetic impacts or in order provide soft grips around certain areas on separate materials and add more flexibility with rigid parts by eliminating manual work altogether-all without having multiple machines have a need at your company!

Final Words

The overmolding process is a great way to produce complex parts with minimal tooling, and it is useful for all sorts of 3D printing needs. Get in touch with us if you’re interested in learning more about how we can help your company develop new prototypes or market existing products using this innovative process. We love helping companies design their next steps!