Five Reasons Why People trust on China Over-Molding Suppliers

Operating principle of China’s over-molding machine

The operation of China’s over-molding supplier comes from injection molding technology. The heated liquid polymer raw material in the mini injection molding machine is injected under high pressure into injection molds. Moreover, it makes it possible to obtain various small-sized products of any configuration, with walls of various thicknesses.

Molding stages of mini injection molding machines

Products are molded in special molds, the quality of which determines the accuracy of the specified parameters and geometric dimensions.

Moreover, thermoplastic molding in mini injection molding machines carries out in several stages:

- The prepared polymer raw material is loaded into the receiving compartment of the injection molding machine, from where it enters the screw zone, where it is heated and melted.

- Simultaneously, the plates of the molds connect, forming a cavity inside for receiving the molten mass.

- The screw-piston, moving forward, and then supply the polymer mass melted in the screw zone.

- Through the mouthpiece of the plasticizing module, under high pressure, the molten mass is injected into a closed mold. At the same time, the non-return valve, performing the function of dosing the polymeric material, prevents the release of the melt into the pre-mouthpiece zone. Moreover, the air from the injection molding machine will be forced out through the existing air valves and removed to the ventilation system.

- Molded products are kept under the influence of high pressure for the time specified by the program, and then the molds cool.

- As the molds cool down, the pressure gradually decreases.

- The cooled molds open, and the finished products are ejected by an automatic ejector unit.

- The auger returns to its original position.

- The molds connect to pour the next portion of the plastic melt.

Cycle thermoplastic molding

Moreover, it can be from two to three seconds, up to ten minutes, depending on the wall thickness. The configuration of the products and the polymer raw materials used.

The operation of the injection molding machine for micro-molding

Automated control with the help of an integrated controller makes it possible to manage with a small staff of service specialists. However, which can significantly save on overhead costs when servicing the operation of the injection molding machine for micro-molding.

Moreover, security and control systems in case of emergencies will turn off the machines automatically.

Overview of injection molding machine’s model comparison

According to the principle of operation and the location of the main components, all models of standard mini injection molding machines in the horizontal version of the SS series are similar to each other. They have a vertically located mold parting plane with the horizontal injection of molten material.

Moreover, screw diameters, overall dimensions, weight, engine and heater power, clamping force, injection force, and volume of mini injection molding machines are different.

However, the main classification indicators are the efforts required to lock the mold, providing a closure node.

A wide range of models of China’s injection molding machines of the SS series will allow you to choose machines for the manufacture of polymer products with the required performance for various purposes.

Steps of the injection molding process

Injection molding is a rather complex physical and chemical process, which consists of the melting of thermoplastic materials, followed by the transfer of the mass into the mold cavity, which is cooling then, and molding the required geometry.

Let’s consider this process in more detail.

The minimum set for the production of plastic products includes the purchase of the material and the manufacture of a mold for molding a specific product.

Moreover, after installing the injection molding machine, connecting it to the electrical network, supplying water for cooling the hydraulics and mold channels. The start-up and debugging of the molding process itself begin.

You need to heat the material in the screw pair

Modern injection molding machines have protection against the so-called cold start. Moreover, electronics simply will not let you turn the screw without reaching the temperature of the melted mass to the desired values. Thus, the screw will only rotate if the mass melts and there is a molten state.

The principle of operation of the injection molding machine

Injection molding machine – specialized equipment for injection molding of thermoplastics. Now, this is the most used way to create parts from polymer materials for several reasons:

- High manufacturability;

- Excellent performance;

- Possibility of automation;

- No further machining is required.

Moreover, thermoplastics, which are necessary for molding, have an extensive list of physical and chemical indicators.

The manufacturing process of Injection molding

China’s over-molding suppliers‘ consumables are thermoplastic polymer particles. However, the manufacturing process takes place in several stages:

- Drying plastic material;

- Placing the plastic material in the receiving compartment of the machine;

- Pouring the plastic material into the screw of the equipment and melted;

- Then the plastic material enters the mold with the help of a piston;

- Passing the sprue cavities, filling the mold;

- The plastic solidifies in a chilled form;

- The mold opens, with the molded product finished.

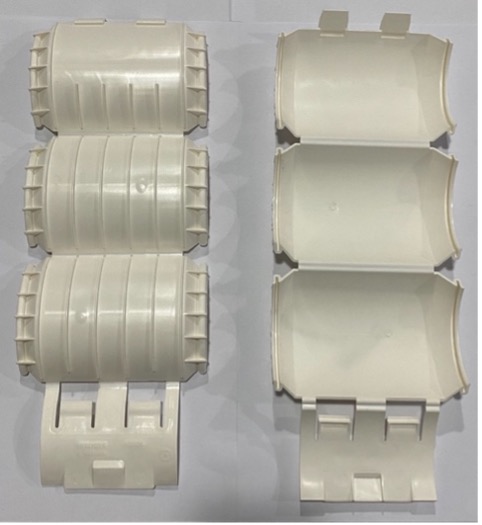

Injection molding machine’s design

The main parts for the operation of the machine are the plasticizing unit and the clamping unit, which move with the help of hydraulic actuators and an electric motor. Moreover, the injecting unit manages all stages of electric and hydraulic drives and also sets the cycle settings.

However, to heat up the material, the operator sets the temperature values for each zone, which can be from 3 or more, depending on the design of the injection molding machine and its size. Typically, the required temperature values for the zone specified by the manufacturer of thermoplastic materials.

The installation of the injection mold

While the plastic material is heated in the screw pair, you can proceed directly with the installation of the mold. To do this, the plates of the Injection molding machine’s clamping units are bred; the mold is placed in the cavity between them, centered on the fixed plate by introducing a centering ring into the plate cavity.

Moreover, the operator gradually closes the plates until the movable plate comes into contact with the end face of the mold. After these operations, the mold fixes to the plates by means of bolts or clamping systems. However, they are usually supplied with injection mold.