How to choose Injection-molded car components?

What are the Injection molded car components?

When choosing to produce your products, parts, or components through thermoplastic Injection-molded car components, it is necessary to pay special attention to the mold design.

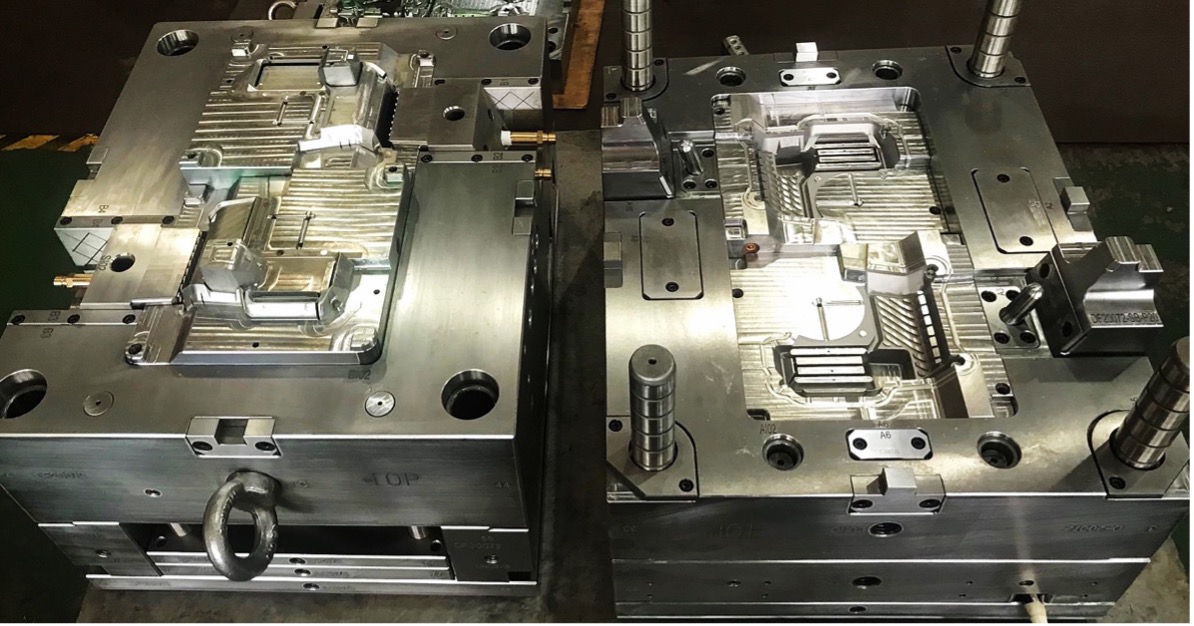

The injection mold is responsible for shaping the resins, being essential for the quality of the final result.

The injection mold must guarantee not only the desired design but also a high level of production and low maintenance requirements. To achieve these characteristics, mold design must consider several technical factors.

Injection-molded car components process

Thus, mold design is an essential process that requires the application of specific and specialized knowledge so that the investment in it brings satisfactory returns. Problems during the design phase lead to losses, waste, and rework.

Come to us to understand the importance of Injection molded car components design and to know the main factors to be during this step.

Please keep reading then!

Mold design: shaping your products

One of the factors that make thermoplastic injection one of the main production processes today is its ability to meet the most varied design needs and offer large-scale production.

Several factors influence thermoplastic injection, such as:

- Type of injection machine;

- Temperature;

- Pressure;

- The mold;

- The component that receives the resin from the Injection molded car components, is responsible for the design and properties.

Injection-molded car components Impact the results

The mold, however, not only impacts the results obtained with the injection project but also its costs. A poor quality mold, for example, can lengthen the production cycle and put more demands on machinery, increasing the risk of breakage and maintenance needs.

The mold project comprises more than the design of the grooves designed to give the resins the desired shape, but a series of factors that aim to make it more

- Functional,

- Productive,

- Resistant,

- Capable of meeting the specific need

In this way, we can define the mold design as the most important step of thermoplastic Injection-molded car components, as it directly impacts the rest of the process.

Preparing the thermoplastic injection mold project

To prepare a mold project that allows the construction of quality tooling and that works in favor of your results, it is necessary to consider some basic guidelines during this process.

The beginning of the mold project development must be marked by gathering all the necessary information for elaboration. This step is important to avoid back and forth searching for uninformed data.

Among the information that must be included in the project, we highlight:

Product information:

The design of a product injects is easy to provide on paper or electronically, and in some cases, a physical sample also works on, whether prototypes or with the existing product.

This drawing provides the most important information to the designer. It is from the drawing that the person responsible for the project defines the Injection molded car components point, closing lines, product extraction side, extraction method, need for moving elements, inclined pins, among others.

At this stage, it is important to evaluate the technical and aesthetic issue of the product, evaluating whether the existing premises facilitate or hinder the injection process.

Selection of the injection machine:

Choosing the ideal injection molding machine for the mold to be built is another important step in the development of the project. The assembly, machine, and mold must meet the needs of the product and productivity.

Factors such as the number of the mold cavity and other mold configurations must be the ideal Injection-molded car components for the project.

Dimensions of the Injection molded car components:

The project must present the dimensions of the mold. It is must be clearly explained, facilitating the visualization of information, as well as justified through calculations that demonstrate the reason for these choices.

Choice of materials for Injection-molded car components:

The material in which the mold is manufactured also affects the results achieved with it, and this must be careful, gritty, and justify the choice in the project.

It is important to understand that the mold design is a technical document, so all information in the mold must be based on calculations.

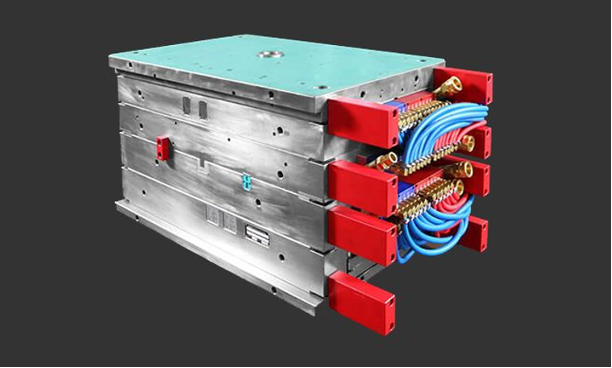

Tool working mechanisms of the Injection molded car components:

The mold design must determine the working mechanisms of the tool, that is, the characteristics related to its use.

This conception of how the tool works in the project is important to obtain a functional mold.

The Importance of Mold Design

As you may have noticed, mold design is a technical step that requires a range of expertise from the designer. Furthermore, creating an ideal design requires in-depth knowledge of mold making and tooling equipment.

The Injection molded car components determine:

- Building tolerances;

- Contractions located in the part;

- Positioning of cooling holes;

- Extraction angles;

- Surface finish;

- Location of mold opening lines;

- Configuration of extractors and guide pins;

- The Number and position of Injection molded car components points;

- Food and distribution channels.

Injection-molded car components impact the production process

Thus, the mold design determines both the design and aesthetics of the product, as well as its properties, in addition to directly impacting the production process.

Good mold design is critical to the success of thermoplastic injection. The development of an injection mold, however, is a complex and laborious process. It is required to reconcile the different expectations of the parties involved.

The durability of the Injection molded components

It is not enough for the designer to follow to the letter the aesthetic desires involved in the final product. The mold must be financially viable and capable of offering good durability, which requires working with its simplification

It is noteworthy that mold design is one of the biggest costs in Injection molded car components. So, working with intricate molds can pressure costs to make the product unfeasible for the market. The solutions applied by the designer need to meet the productive and constructive aspects of the business.

Conclusion

In order that you can make conscious choices, we wrote this article. This article will tell you what to consider when developing the mold design. It is to achieve the best results with thermoplastic injection for everyone involved in the process.