2022 China Over-Molding Injection Molding Supplier

Control panel for injection molding machine

To choose the most suitable over-molding injection molding supplier for specific purposes, you need to know its characteristics. The clamping force is important. With its help, you can get an idea about the options and dimensions of the equipment.

Plastination and injection unit of the molding cycle

This part is the main one in the whole molding cycle. The plastination and injection unit melts the thermoplastic and feeds it into the mold.

Step by step operation of the device:

- Place the material into the hopper;

- Further, the material is fed into the material cylinder;

- Moreover, the screw rotates and transfers it to the nozzles;

- Plastic heats up and melts;

- Similarly, plastics are injected into the mold.

Over-molding injection molding supplier: Cycle stages

Moreover, the casting cycle carries out in several stages of different duration:

- a) Closing the mold – Moving the injection unit forward – Feeding into the forming cavity;

- b) Pressure treatment;

- c) Movement of the injection unit back – Plasticization – Return of the screw;

- d) Opening the mold to extract the part.

Most of the time is spent working under pressure and cooling the part. Moreover, as a rule, the duration of these processes depends on the thickness of the walls of the product. Machining parts with thin walls takes more time in the dry cycle.

Closing and injection: to maintain the desired speed

The first stage is divided into several parts with different injection speeds. Moreover, it is possible to maintain the desired speed of the passage of plastic through the mold runners.

The auger maintains the material injection pressure

In the second stage, the auger maintains the material injection pressure. If the pressure exceeds the desired values, the parts of the mold will move apart, and the material will flow into the slots.

Plasticizing: the material is fed into the screw cavity

At this stage, the auger rotates and returns to its original position. Simultaneously with this process, the next portion of the material feds into the screw cavity.

Mold opening: the product is removed from the mold

The product cools in the mold, then the movable plate moves away, revealing the part formation cavity. As a rule, the equipment is designed to remain the product on the mold when it opens– the movable half. The product can be removed from the mold by pushers driven by a hydraulic cylinder of the machine with a shank.

For many years, our company has been manufacturing molds of various complexity for the production of plastic parts, which are produced by injection molding, using modern technologies that combine the use of the best components from world-famous manufacturers with the latest engineering solutions.

Over-molding injection molding supplier: calculating the cost

The mold production process begins with a competent technical assignment, that is calculating the cost, which is given to us by the customer at the stage of calculating the cost of future toolings. Moreover, competent terms of reference guarantee the accuracy of execution, as well as the receipt of a personalized product that will satisfy all the requirements.

Allows the Customer to receive a comprehensive service for 3D modeling

We can not only manufacture molds but also calculate the geometry, strength, light reflection, and transmission. This allows the Customer to receive a comprehensive service for 3D modeling of the over-molding injection molding supplier with the involvement of our designers.

Often, clients come to us with a visual representation of a future product, either a textured sample or 2D drawings. Moreover, in such cases, our designers themselves will develop a three-dimensional model of the product for the subsequent design of the mold.

At the development stage, the customer needs to specify as accurately and in detail all the nuances of the future product, geometry, properties, material used, surface, performance requirements, and so on.

The more details about over-molding injection molding supplier

Less time will be required for subsequent approvals and refinements of the mold design.

Moreover, we will proceed with the mold design. Here we take into account the requirements for productivity, ease of maintenance of equipment, and other important points that directly affect the life cycle of the product and its cost.

We acquaint the customer with the received drawings of the mold, who makes his own changes or approves the future design of the mold.

Moreover, after the design of the tooling is approved by the customer, the purchase of components and materials for the manufacture of the future molds will begin.

Heat treatment of molds

The inserts are placed to increase the wear resistance of the forming cavities. For example, a molding machine made of raw steel allows you to produce no more than 100,000 closures, and a heat-treated one allows you to increase the resource to 3 million. Moreover, not all steel can be heat-treated, for this purpose we choose special tool steel with a high content of carbon and alloying elements.

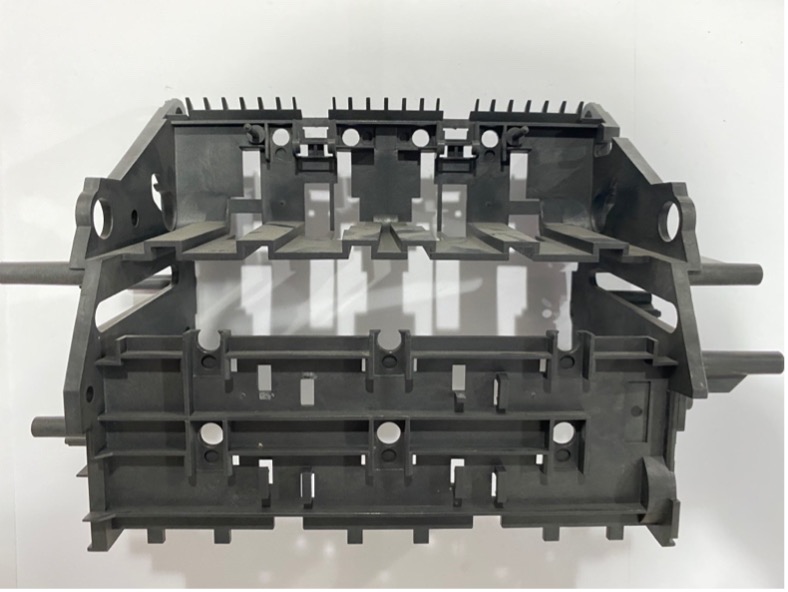

The process of finishing milling and electro-erosive machining

Finishing milling of hardened steel carries out in over-molding injection molding supplier using special carbide cutters at high speeds. For electro-erosive machining (piercing), a copper electrode uses, which burns out the required geometry of the forming cavity. Next, the molds will be polished.

In parallel with the process of manufacturing the molded parts, the mold package is machined. This process includes casing milling, backing plate milling, cooling channel milling, etc.

Assembly: pre-test the mold on an injection molding machine

Moreover, all parts transfer to the assembly shop, where workers assemble and pre-test the mold on an injection molding machine.

Testing: for adjustment during commissioning

The mold securely attaches to the clamping plates. After which all parameters are set, followed by a test injection of the material into the cavity. During testing, the molding card issues should be paid attention to. This is subsequently sent to service engineers and the Customer for adjustment during commissioning.

Based on the test results, test samples send to the customer to check the geometry and approve textured samples. Moreover, according to the results of the comments received, the molds will finalize with the subsequent shipment.

In conclusion, after signing the certificate of approval of the received samples, the molds will be preserved by applying grease and packed in wooden boxes for subsequent transportation to the customer.