What to Know About Multi and 2-Shot Injection Mold?

Your Comprehensive Guide on 2-Shot Injection Mold

Are you new to shot plastic injection molding? If yes, then you might think that the process is extremely complex. But, this is not the actual case. In fact, the process is quite easy and far from being complex. The 2-shot injection mold is the primary type of injection molding.

So, if you want to know more about the process, then keep reading. We will tell you everything you might want to know in this guide.

What is 2-Shot Injection Mold?

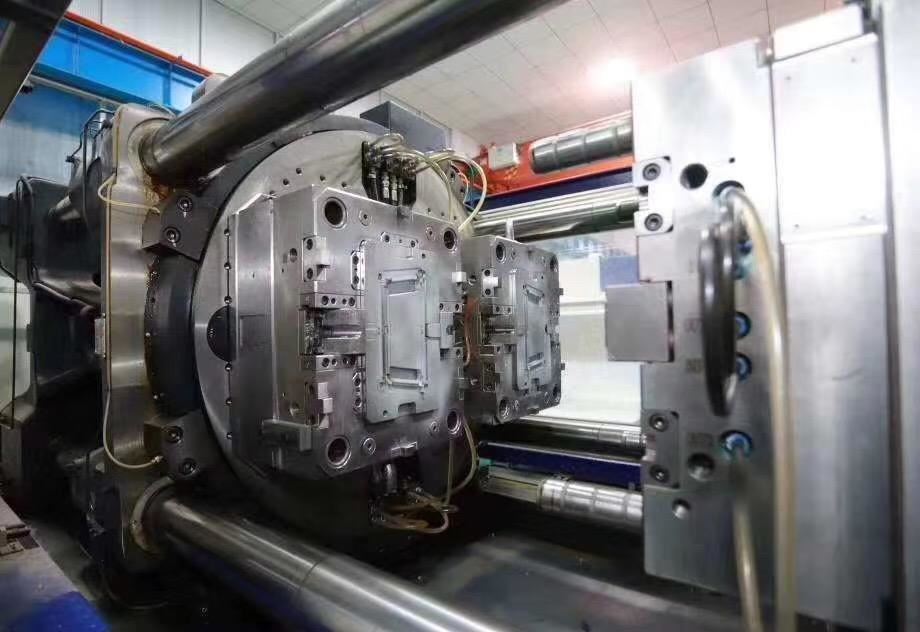

Also known as multi-shot, dual-shot, and double-shot, the 2-shot injection mold is the process of molding plastic. In this process, the manufacturers mold two different types of resins together in one machining cycle. This is what makes it an ideal process for multi-material, multi-color, and complex plastic products.

The Process of 2-Shot Injection Mold

The entire process of 2-shot injection mold revolves around two major steps. While the first step is similar to traditional injection molding, the second step is a bit different from it.

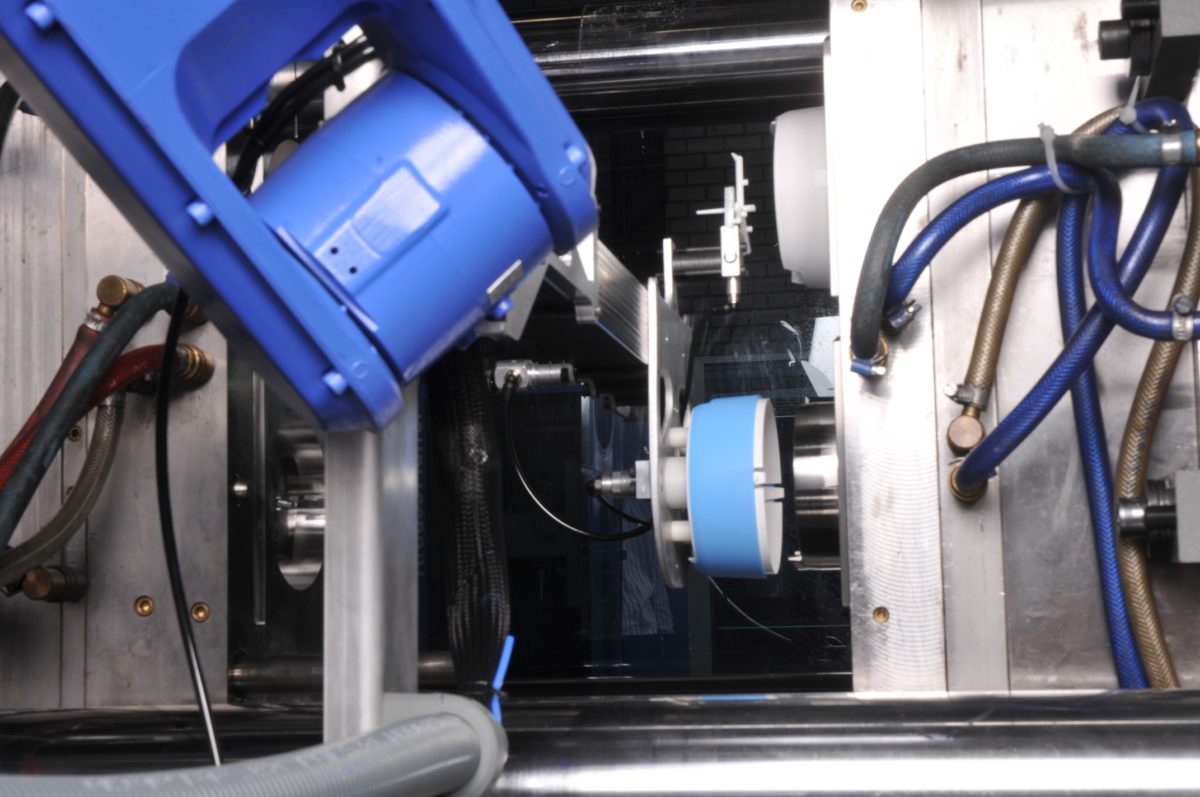

In the first step, the engineers inject a shot of resin into a mold and cool it down to form a solid part. However, in the second phase of the process, the workers transfer the recently-molded parts into a second mold with the help of a rotating platen or a robotic arm.

Here, the plastic receives its second shot of resin. The amount of the required resin depends upon the design that you want to achieve. In the end, the two plastic resins form a molecular bond molded part of the multi-resin is cooled down and ejected.

The entire process is extremely simple and not at all difficult to understand. But, mustering it requires high effort. You need to have attention to detail and a high level of technical expertise for it. Even a little mistake can cost you big money, especially when producing high-volume goods. That’s why many engineers call it a highly difficult process to muster.

For this reason, it becomes extremely critical that you find a high-end supplier that pays attention to details. In addition to this, you should also look for quality scorecards, short-shorts, flow lines, and contingency plans that will help you expand your business capacity.

Once you find the supplier of your choice, you can involve them in the designing phase of your production as well. This will turn out to be great for you as they are capable of identifying potential problem areas and engineering value into your product.

Is 2-Shot injection Mold Technology Toxic?

While some people have the misunderstanding that the 2-shot injection molding technology is toxic, this is not the case. That’s because the entire process is completely harmless. In addition to this, there are not any carcinogens involved as well.

Moreover, according to research, there are no adverse health effects that might affect the health of the workers. However, it is not suitable for medical implants. So, make sure that you do not use them near the machine.

Other than that, it is a completely safe process.

2-Shot Injection Mold Applications

From construction to consumer goods, the 2-shot injection mold applications are utilized in almost every industry. However, its most common applications are as follows.

- Acoustic dampening

- Multi-material components

- Movable segments

- Rigid substrates

What are the Benefits of 2-Shot Injection Mold?

The 2-shot injection mold process offers many benefits over the traditional molding methods. This is what makes it an ideal choice for molding plastic. Let’s take a look at some of these benefits below.

1. Improved Efficiency

The two-shot injection molding process allows the molding of different components with only a single tool. As a result, it reduces the amount of labor that you need for the smooth functioning of your parts. Not only this, but it also eliminates the need to join or weld the components after the welding process is complete.

2. Complex Moldings

Another great advantage of 2-shot injection molding is that it allows complex molding of the plastic parts which is not possible with traditional molding. You can easily create complex mold designs that need multiple materials for smooth functionality. This is why many suppliers prefer this method over traditional methods.

3. Part Consolidation

With the help of the two-shot injection molding, you can reduce the number of components that a finished assembly requires. This eliminates the need for more cost in the production method. As a result, the engineering, development, manufacturing, and other validation costs also reduce.

4. Improved Quality

The engineers carry the process of a 2-shot injection mold with only a single tool. This allows lower tolerances as compared to other molding processes. Not only this, but you also get a high level of repeatability, accuracy, and fewer scrap rates.

5. Low Labor Cost

Another enormous benefit that surfaces with a work area plastic injection molding machine is the lower work cost. When contrasted with different kinds of trim interaction, the work cost is very low in injection molding. That is because this assembling cycle can create plastic parts at an amazingly undeniable level. Accordingly, it builds the expense adequacy and cost-effectiveness of the injection molding technique.

6. You Can Use Multiple Plastics

A two-shot injection molding machine can utilize various sorts of plastics at the same time in the machine. The technique for utilizing numerous plastics in the injection molding machine is known as co-infusion forming. Along these lines, you won’t need to stress over utilizing a particular kind of plastic in the plastic injection molding machine. You can use as numerous kinds of plastic you need with no dread of harm to the machine.

Final Words

Now that you know in detail the process of 2-shot injection mold technology, we hope you can make an informed decision when it comes to choosing between the different injection molding processes. However, if you still have anything else to ask, don’t hesitate to reach out to us. We will be happy to assist you in any we can.